2026 Best Wire Mesh Weaving Machine Features and Benefits?

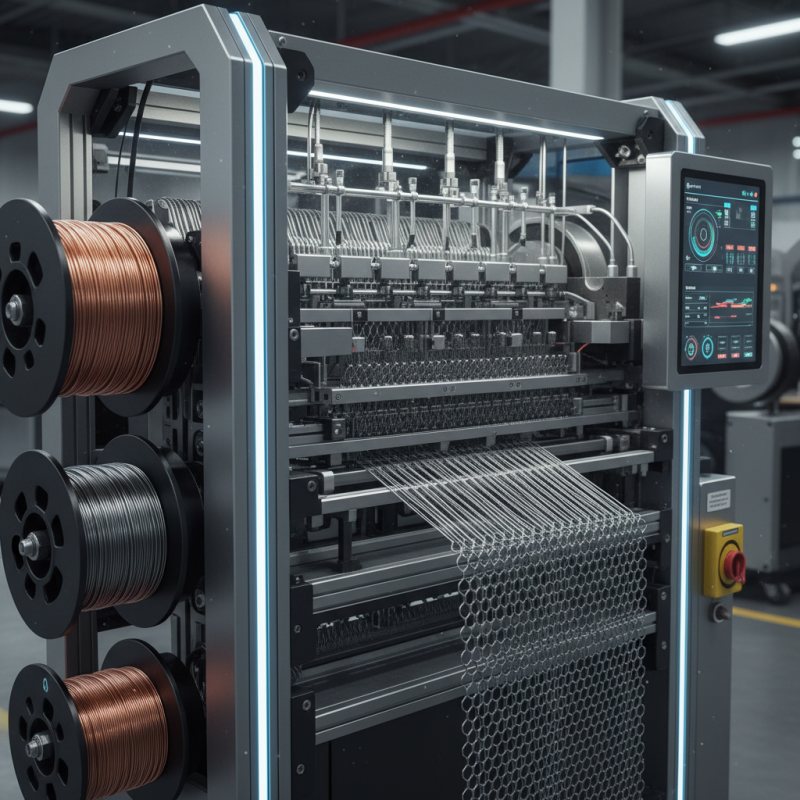

In the world of industrial manufacturing, the wire mesh weaving machine stands out as a crucial tool. This machine plays a vital role in creating high-quality wire mesh products. Businesses rely on its efficiency and versatility for various applications.

The 2026 models of wire mesh weaving machines promise enhanced features and benefits. They are designed to improve productivity and reduce waste. With advancements in technology, these machines now offer better precision and faster operation. However, some users may find the learning curve steep. Adjusting to new features can be challenging.

Investing in a modern wire mesh weaving machine can significantly impact production outcomes. The durability and strength of the wire mesh products produced are essential. Companies must weigh the upfront costs against potential long-term benefits. Awareness of these factors is critical for making informed decisions.

2026 Wire Mesh Weaving Machine: Overview of Innovative Features

In 2026, the wire mesh weaving machine evolves with innovative features tailored to diverse industries. These machines now incorporate advanced automation technology. Reports indicate that the use of automation can enhance production efficiency by up to 30%. This transformation allows for quicker setups and easier adjustments in production lines.

Another exciting feature is the integration of smart sensors. These sensors monitor machine performance in real-time. This leads to reduced downtime and maintenance costs. Organizations can expect up to a 25% reduction in operational expenses when employing smart technology.

**Tip:** Regular training is crucial for operators. Even the best machines require skilled hands.

Flexibility is key. The latest machines can handle various mesh sizes with minimal adjustments. However, some users report that frequent changes can impact quality. This inconsistency prompts a need for constant quality monitoring.

**Tip:** Keep a detailed log of production metrics. This helps identify patterns and adjust processes accordingly.

As technology continues to advance, adopting these machines may require a learning curve. Users must be prepared to continually adapt to maximize their benefits. It's important to engage with user feedback to refine processes.

2026 Best Wire Mesh Weaving Machine Features and Benefits

| Feature | Description | Benefits |

|---|---|---|

| High Speed Operation | Capable of weaving at speeds up to 200 meters per minute. | Increases productivity and reduces manufacturing time. |

| Automatic Tension Control | Maintains consistent tension across the weaving process. | Ensures high-quality mesh with minimal defects. |

| User-Friendly Interface | Intuitive touchscreen controls for ease of operation. | Reduces training time and improves operational efficiency. |

| Energy Efficient | Designed to consume less power during operation. | Lower operational costs and reduced environmental impact. |

| Modular Design | Can be easily expanded or customized based on needs. | Flexibility to adapt to changing production requirements. |

| Enhanced Safety Features | Equipped with safety guards and emergency shutoff. | Increases workplace safety for operators. |

| Remote Monitoring Capabilities | Allows operators to monitor the machine remotely. | Improves maintenance and reduces downtime. |

Key Benefits of Advanced Wire Mesh Weaving Technologies in 2026

The advancements in wire mesh weaving technology in 2026 bring numerous benefits to industries. Speed and efficiency are at the forefront. Machines are now able to operate at impressive speeds. This improves production rates significantly. Operators can expect higher output with less downtime. This efficiency translates to cost savings for businesses.

Another key benefit is the enhanced versatility of the machines. They can handle a variety of materials and weave patterns. This flexibility meets diverse customer demands in different sectors. Companies can adapt quickly to changing market needs. However, this rapid adaptability poses a challenge. Workers need training to operate sophisticated machines effectively.

Additionally, the quality of the wire mesh produced has improved. New technology ensures tighter tolerances and better strength. This reliability is crucial for construction and safety applications. Yet, it's worth noting that the learning curve can be steep. Some companies struggle with the transition. This suggests that investment in training is essential to fully reap the benefits.

Performance Metrics: Speed and Efficiency of Modern Weaving Machines

Modern weaving machines have transformed the textile industry. Performance metrics like speed and efficiency are crucial. In 2026, the best wire mesh weaving machines enhance productivity. They operate at impressive speeds, weaving complex patterns quickly. This increases output without compromising quality.

Tips: Regular maintenance is key for optimal speed. Dust and debris can slow down performance. Check all moving parts frequently to avoid breakdowns. Adjust settings based on material type to maximize efficiency.

Efficiency also boils down to energy usage. Some machines are designed to consume less power while maintaining high output. However, not all machines are equally efficient. It's essential to analyze energy costs versus production benefits. A machine might be fast, but if it drains energy, re-evaluation is necessary.

Invest in training for operators. A skilled operator can dramatically affect productivity. They should understand each machine's capabilities and limitations. This knowledge can prevent errors that waste time and materials.

Performance Metrics of Modern Weaving Machines

This chart illustrates the performance metrics of modern weaving machines, showcasing their speed in meters per minute, efficiency percentage, and power consumption in kilowatts. These metrics are crucial for assessing the overall productivity and sustainability of the machines used in the textile industry.

Comparative Analysis: 2026 Models vs. Previous Generations in the Market

The 2026 models of wire mesh weaving machines show significant advancements compared to previous generations. These modern machines offer enhanced speed and efficiency, allowing users to increase their production rates. Innovation in technology has led to better precision in weaving, resulting in consistent quality throughout each batch produced.

The design of these new models focuses on user-friendliness. Operators can easily navigate the controls, reducing the learning curve. However, some users might feel overwhelmed by the range of options available. It’s crucial to understand which features fit your needs best.

**Tip:** Familiarize yourself with the machine’s manual. It often contains insights that can save you time and reduce errors.

Another improvement is material compatibility. New machines can handle a variety of wire types and gauges. This flexibility benefits manufacturers who need to switch between products frequently. But, it’s essential to ensure the machine settings match the specific wire characteristics to avoid malfunction.

**Tip:** Test small batches when using new materials. This strategy can help identify potential issues early.

Industry Applications: Versatility of Wire Mesh Weaving Machines in Various Sectors

Wire mesh weaving machines are highly versatile tools for various sectors. They are prominently used in construction, filtration, agriculture, and aerospace. According to a recent industry report, the global wire mesh market is projected to reach $6.5 billion by 2026. This reflects an increasing demand for wire mesh across diverse applications.

In construction, wire mesh provides excellent reinforcement in concrete. It enhances strength and durability. The aerospace sector often requires specialized mesh for precision parts. This highlights the need for adaptable weaving machines. Agriculture benefits from wire mesh in fencing and pest control. However, not all machines meet the varied demands of these industries. Some may lack the precision or material quality needed for high-end applications.

The flexibility of wire mesh weaving machines lies in their ability to produce different mesh sizes and patterns. For instance, machines can create fine meshes for filtration or larger sizes for construction. However, the adaptation process can be flawed. Some machines struggle with consistency in wire tension. It's crucial for manufacturers to address these challenges to meet industry needs effectively. Ultimately, the potential for innovation is vast, but execution matters significantly.