2026 Best Injection Machine Robot for Efficient Manufacturing?

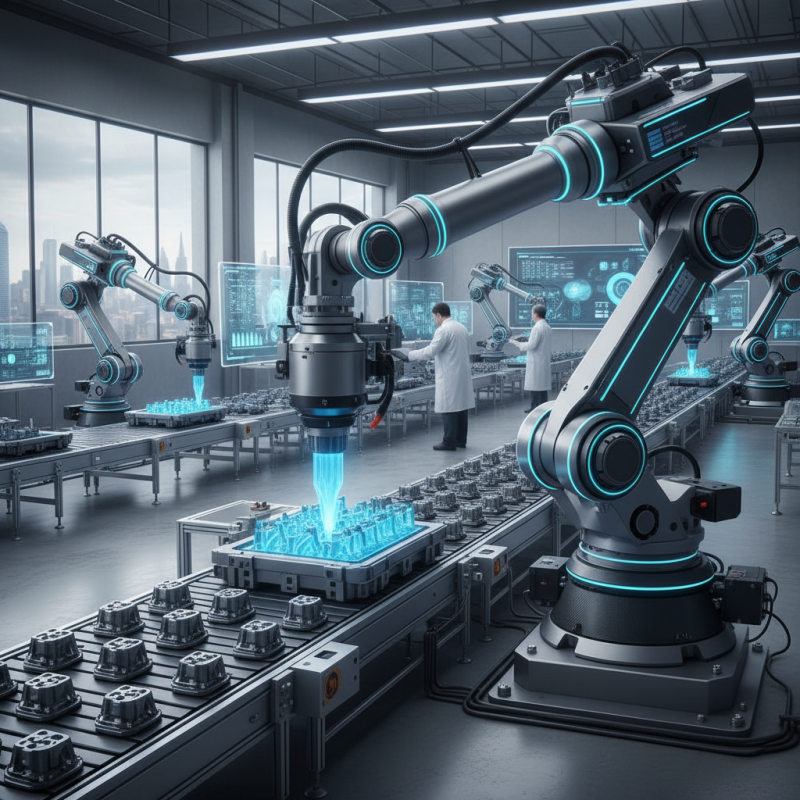

As industries aim for greater efficiency, the role of the Injection Machine Robot is becoming increasingly critical. According to a report by Markets and Markets, the global robotic automation market is expected to reach $23 billion by 2026. This surge reflects rapid advancements in technology and increasing demand for precision in manufacturing processes. Injection Machine Robots are at the forefront, streamlining production and enhancing output quality.

Despite these advancements, challenges remain. Many manufacturers struggle with integrating automation into existing systems. The learning curve can be steep, and operational disruptions often occur. However, the benefits of using Injection Machine Robots, like reduced labor costs and increased cycle time efficiency, outweigh these concerns. The potential for error reduction and improved product consistency cannot be ignored.

In 2026, the best Injection Machine Robots will likely be characterized by their adaptability and ease of use. Manufacturers must remain vigilant and continually assess the effectiveness of these technologies. Striking the right balance between automation and human oversight is essential. This reflection will be crucial as companies adapt to evolving market demands and technological innovations.

Overview of Injection Machine Robots in Manufacturing

Injection machine robots are transforming the manufacturing landscape. These machines enhance production efficiency and reduce operational costs. Industry reports indicate that automated injection molding can decrease cycle times by 30% to 50%. This improvement allows manufacturers to increase output without significant capital investments in infrastructure.

The integration of robots in injection molding processes is witnessing rapid growth. A recent survey found that over 45% of manufacturers are adopting robotic solutions for various tasks. These robots not only handle complex molding but also optimize material usage. However, the transition to automation is not without challenges. Companies must invest in employee training and address resistance to change among workers.

Precision and consistency are vital in manufacturing. Reports show that robotic systems can achieve accuracy levels greater than 0.1 mm. Despite this, maintaining this precision requires regular maintenance and calibration. Manufacturers should evaluate their systems continuously. This reflection can help identify areas that need improvement. Balancing efficiency with quality remains a crucial objective in the evolving manufacturing sector.

Key Features to Consider for Injection Machine Robots

When considering an injection machine robot for efficient manufacturing, several key features stand out. First, precision and accuracy are non-negotiable. According to a recent industry report, precision in injection molding can reduce material waste by over 20%. This is crucial in maximizing profitability and sustainability.

Another vital feature is speed. Modern injection machines often have cycle times under 30 seconds. This increased efficiency can significantly boost production rates, offering a competitive edge in the market. However, not all robots achieve optimal speeds equally. Users must evaluate programming capabilities and ease of integration with existing systems.

Energy efficiency is also important. Many injection machine robots now come equipped with motors that use up to 50% less energy compared to older models. Yet, the initial investment might be daunting for some manufacturers. Balancing upfront costs against long-term savings requires careful reflection. Overall, examining these features thoroughly can lead to better decision-making and improved manufacturing outcomes.

2026 Best Injection Machine Robot for Efficient Manufacturing

Top Brands and Models for Injection Machine Robots in 2026

In 2026, the landscape for injection machine robots is evolving. Many manufacturers seek efficiency and speed. Industry reports indicate that automation can boost productivity by up to 30%. This surge is driven by advancements in robotics technology. Precision is key. Modern models offer enhanced accuracy, reducing waste during production.

When selecting an injection machine robot, consider versatility. Models that adapt to various materials can save time. Data suggests that robots with quick-change capabilities are becoming essential. Tips for optimizing use include regular maintenance checks. Preventative care can extend a robot’s lifespan and performance.

Moreover, training staff to fully utilize these robots is vital. Studies highlight that companies with well-trained personnel see significant performance increases. However, it’s essential to reflect on the integration process. Some organizations struggle to introduce robots seamlessly. Recognizing these challenges can lead to better implementation strategies. Balancing technology and human skill is crucial for future growth.

Cost-Benefit Analysis of Investing in Injection Machine Robots

Investing in injection machine robots can significantly enhance manufacturing efficiency. These robots can automate repetitive tasks, minimizing human error. As a result, production rates can improve dramatically. However, the initial investment for these advanced machines can be substantial. Companies must assess whether the long-term savings justify the upfront costs.

A detailed cost-benefit analysis is crucial. Calculate potential savings from reduced labor costs and increased production. Yet, hidden costs may arise. Maintenance, training, and downtime can impact the financial picture. Factoring these elements into the equation ensures better decision-making. Continuous evaluation is necessary. What worked well last year might not hold true today.

Moreover, consider the adaptability of these robots. Technology evolves rapidly, and machines that are state-of-the-art today may be outdated tomorrow. Investing in easily upgradeable systems could save money in the long run. It's essential to remain flexible and open to improvement. The path to automation demands careful thought and reflection about future needs.

Future Trends in Injection Machine Robotics and Manufacturing Efficiency

The landscape of injection machine robotics is rapidly evolving. Innovations are emerging to enhance manufacturing efficiency. Companies are investing in smarter robots equipped with advanced sensors. These robots can monitor their environment and adapt to changes. This flexibility allows for smoother production processes. However, the integration of AI still poses challenges.

Future trends indicate a shift towards collaborative robots, or cobots. These machines work alongside human operators. They can perform repetitive tasks, alleviating human workload and reducing strain. Implementing cobots requires careful planning. Companies must consider worker safety and ergonomics. Combining human intuition with robotic precision could streamline operations significantly.

Yet, not all advancements come easy. The initial costs of upgrade can be high, leading to hesitance from smaller manufacturers. There is also a need for training personnel. Workers must learn to interact with new technology effectively. Without proper training, automation can lead to confusion or inefficiencies. The path forward is complex but promising, as the future of injection machine robotics unfolds.