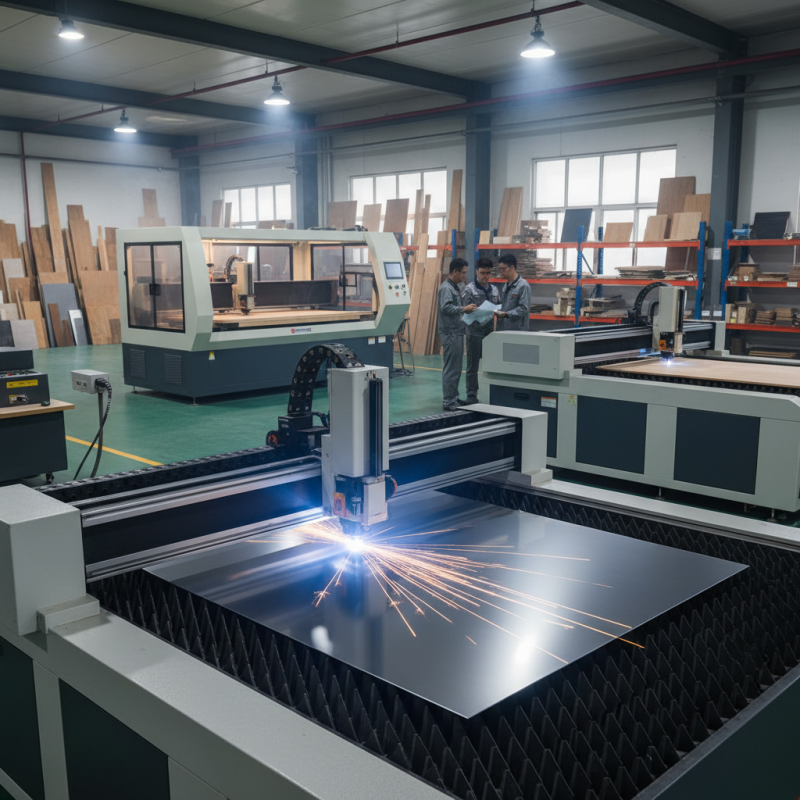

How to Choose the Right Laser Cutting Machine for Your Needs?

Choosing the right laser cutting machine is crucial for your projects. This decision impacts efficiency and quality. Many factors influence your choice, including materials, thickness, and precision requirements.

With various options available, it can be overwhelming. Do you need a CO2 laser or a fiber laser? Consider your common materials. For instance, CO2 lasers are great for wood and acrylic, but fiber lasers excel with metals.

Reflect on your specific needs. Are you prioritizing speed or detail? A powerful machine may seem appealing, but it could lead to overspending. Finding balance is key. Take the time to evaluate your options and think critically about your requirements.

Understanding the Different Types of Laser Cutting Machines

When selecting a laser cutting machine, understanding the types available is crucial. CO2 lasers are popular for cutting non-metal materials, such as wood and acrylic. They work well for intricate designs. Fiber lasers are effective for metals like steel and aluminum. They offer faster cutting speeds and higher precision.

Tips: Consider your primary material. If you cut both metal and wood, a dual-laser system might be beneficial. Meanwhile, the quality of the lens and mirror can impact performance greatly.

Another type is the crystal laser. While less common, they are powerful and suitable for thicker materials. Their higher cost can be a drawback. User feedback on these machines often highlights the learning curve involved. It's essential to weigh the advantages against your specific needs.

Tips: Do thorough research before purchase. Read reviews and ask for demonstrations if possible. Understanding maintenance requirements can help prevent future issues.

Key Factors to Consider When Selecting a Laser Cutting Machine

Choosing the right laser cutting machine involves several critical factors. Understanding your specific needs is key. Consider the material types you will be cutting. For instance, metals, plastics, and wood require different laser specifications. Data shows that 75% of businesses report improved efficiency after selecting the right machine. This implies that informed decisions significantly affect productivity.

Power and speed are also crucial factors. A typical CO2 laser cutter operates at around 60-150 watts, effectively handling various materials. However, higher wattages can lead to faster cutting but may increase initial costs. A study highlighted that machine speed can influence operational costs by up to 30%. Balancing speed and power according to available budgets is essential.

Maintenance requirements should not be overlooked. Machines with high uptime may have hidden costs. Insufficient maintenance can lead to unexpected downtimes. Almost 20% of users encounter issues due to improper care. Ensure you understand what maintenance involves and plan accordingly to avoid future issues. So, reflect on these elements closely as you navigate your selection.

Evaluating Material Compatibility for Laser Cutting Machines

When selecting a laser cutting machine, understanding material compatibility is crucial. Different materials react uniquely to laser cutting. For instance, acrylic is popular due to its clear edges and fast cutting speed. Wood can produce great designs but may require adjustments in settings to avoid burning. Metal, on the other hand, needs precise control to achieve flawless results.

Some materials can be tricky. For example, cutting rubber can release harmful fumes. It's essential to have proper ventilation to protect the operator. Additionally, some fabrics may fray at the edges. Testing on scrap pieces can help determine the right settings and avoid costly mistakes.

Experimentation is key. Each type of material has its quirks. What works for one substance may not suit another. Keeping a record of settings for each material can save time in future projects. Reflection on previous experiences will help refine your process. Understanding material behavior improves your chances of achieving high-quality cuts.

How to Choose the Right Laser Cutting Machine for Your Needs? - Evaluating Material Compatibility for Laser Cutting Machines

| Material Type | Recommended Laser Type | Power Range (Watts) | Max Thickness (mm) | Cutting Speed (mm/min) |

|---|---|---|---|---|

| Acrylic | CO2 Laser | 40-150 | 20 | 1000 |

| Wood | CO2 Laser | 40-150 | 40 | 600 |

| Metal | Fiber Laser | 500-4000 | 10 | 300 |

| Fabric | CO2 Laser | 20-100 | 5 | 1500 |

| Paper | CO2 Laser | 20-80 | 3 | 2000 |

Assessing the Size and Power Requirements for Laser Cutting

Choosing the right laser cutting machine requires careful consideration of size and power requirements. The ideal laser cutter should match your specific production needs. An industry report from the Laser Institute of America states that focus on power output is crucial. Higher wattage allows for cutting thicker materials. For instance, a 150W laser can effectively cut through 10mm acrylic, while a 200W model might handle metals. Evaluate the materials you will work with to determine the right power for your machine.

Size plays a significant role in your decision. If your projects involve large sheets, opt for a machine with a bigger bed size. A report by Research and Markets suggests that larger-scale operations may require machines with cutting areas exceeding 1200mm x 800mm. Ensure your chosen model can accommodate the dimensions of the materials you frequently use. Remember, insufficient bed size may limit your productivity.

Tip: Always account for future growth. If you plan to expand your capabilities, consider a machine that can handle larger materials. An underpowered or undersized machine can lead to frustration and inefficiencies. Don’t hesitate to ask for user reviews or performance insights from current owners. Your investment should support not just your current needs but future aspirations as well.

Analyzing Budget and Cost Efficiency in Laser Cutting Machines

When considering a laser cutting machine, budget is a crucial factor. According to recent industry reports, the average cost of a quality laser cutter ranges from $10,000 to $300,000, depending on its capabilities. A more expensive model may offer higher precision and speed. However, it's essential to assess whether these features align with your actual cutting requirements.

Tips: Assess your cutting volume. If your projects are small-scale, a lower-priced machine may suffice. High-end machines might not be necessary for simple tasks. Evaluate the long-term operational costs, including maintenance and energy consumption. Some machines may appear cheaper upfront but can lead to higher costs over time.

Be mindful of the trade-offs. A budget-friendly option may lack advanced features, which could limit its versatility. Conversely, a high-priced machine might exceed your needs. Analyze how frequently you will use the device and what materials you will cut. A well-rounded understanding will guide you in choosing the right equipment without overspending.

More often than not, laser cutting machines can be a significant investment. Balancing initial costs with potential returns is vital. Research customer reviews on performance and reliability instead of solely relying on specifications. This approach allows for a pragmatic view of how a machine fits into your overall workflow.