How to Evaluate Quality When Buying Used Lab Equipment for Your Research Needs

When embarking on the journey of selecting used lab equipment for your research needs, understanding the quality of these items is paramount to ensuring reliable and accurate results. The market for used lab equipment offers a myriad of alternatives that can cater to various research requirements, and navigating through these options necessitates a keen eye for detail and a solid evaluation process. In this post, we will explore how to effectively assess the condition and performance potential of used lab equipment, while considering factors such as historical performance, seller credibility, and warranty options. By arming yourself with the right knowledge and evaluation techniques, you can make informed decisions that not only save you money but also support the integrity of your research outcomes.

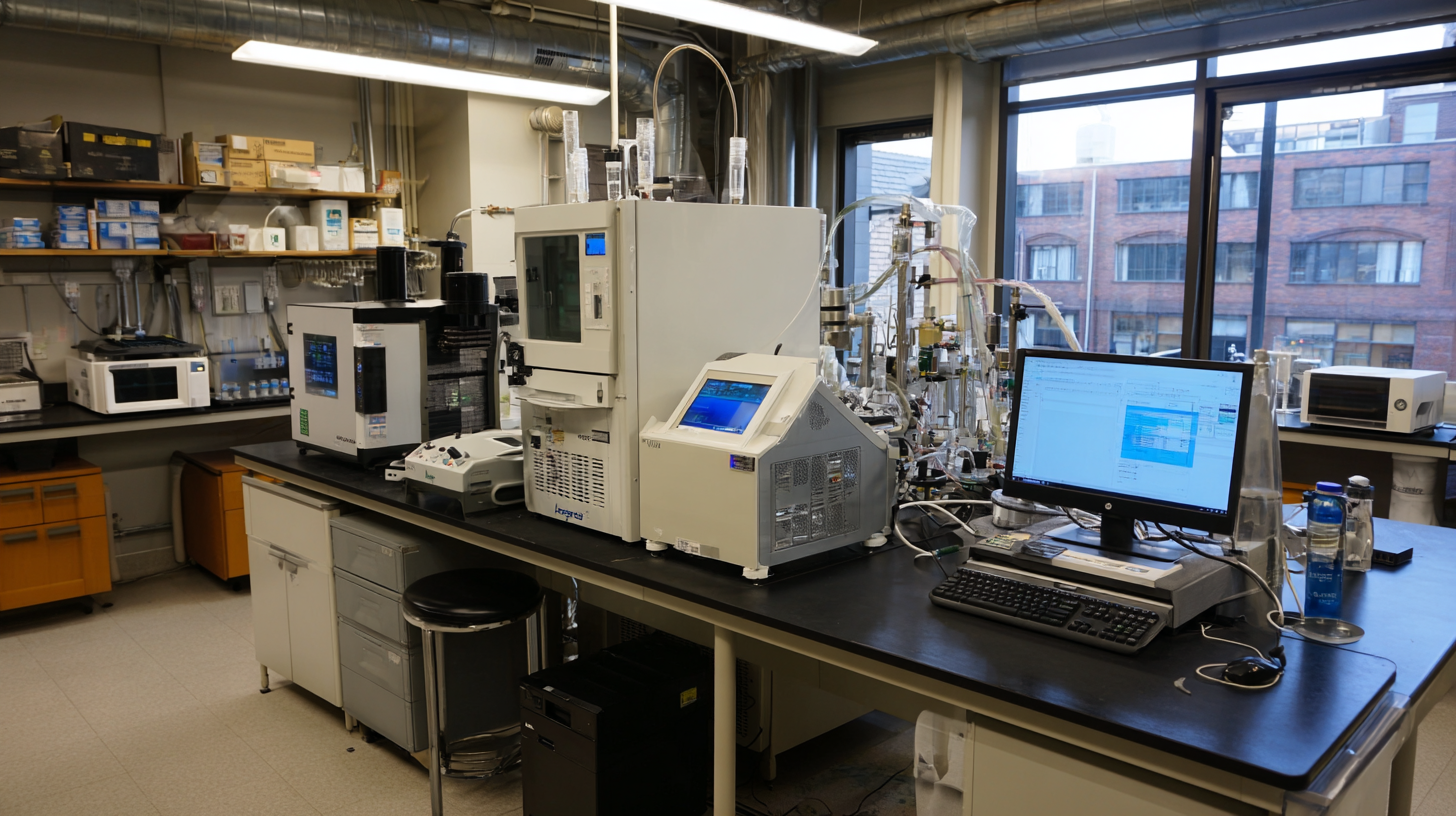

Assessing the Age and Condition of Used Lab Equipment for Optimal Performance

When purchasing used lab equipment, evaluating the age and condition is crucial for ensuring optimal performance. Start by checking the manufacturer's specifications and service history. Equipment that is too old may not only be less reliable but also incompatible with current technologies. Look for any documentation that provides insight into previous use, maintenance, and repairs. This information can help you understand how well the equipment has been maintained over the years.

In addition to age, a thorough physical inspection of the equipment can reveal much about its condition. Look for signs of wear and tear, such as corrosion, cracks, or loose parts. Testing functionality where possible is important; ensure that the equipment performs all necessary operations smoothly. Asking previous users about their experiences with the equipment can also provide valuable insight. This comprehensive assessment will aid in making an informed decision, ensuring that the used lab equipment meets your research needs without compromising quality.

Understanding Calibration and Maintenance Records to Ensure Accuracy

When purchasing used lab equipment, understanding its calibration and maintenance records is crucial for ensuring accuracy and reliability in your research. A study by the American Association for Laboratory Accreditation (A2LA) indicates that approximately 75% of laboratory errors arise from improperly maintained equipment. Thus, reviewing these records is not just a best practice but a necessary step in safeguarding the integrity of your research.

Calibration records should detail the dates of service, the standards used, and the specific adjustments made to the equipment. According to the National Institute of Standards and Technology (NIST), instruments that undergo regular calibration can maintain an accuracy rate of over 95%. This is particularly important in fields such as chemistry and biology, where precise measurements can significantly impact experimental outcomes. Furthermore, checking the maintenance history helps identify any recurring issues, ensuring that the equipment will not fail during critical phases of your research. By prioritizing the examination of these documents, researchers can make informed decisions that ultimately enhance the quality of their work.

Evaluating Warranty and Support Options for Used Lab Equipment Purchases

When purchasing used lab equipment, evaluating warranty and support options is critical for ensuring a sustainable investment. Recent reports indicate that as tariffs escalate, many lab managers are shifting towards certified refurbished instruments, which provide a cost-effective alternative to new equipment. According to industry research, 70% of lab managers are rethinking their procurement strategies, citing warranty terms as a primary factor influencing their decisions. Comprehensive warranties not only safeguard against malfunctions but also ensure access to crucial support services that facilitate seamless integration of the equipment into existing workflows.

Furthermore, the emphasis on customer-centric support services is becoming increasingly important in the digital age. A recent study highlights that labs prioritizing strong warranty and support options experience a 40% reduction in equipment downtime, significantly enhancing research productivity. Companies offering robust support and transparent warranty agreements gain a competitive edge, establishing trust and fostering long-term partnerships with research institutions. As both economic and environmental factors prompt a pivot towards refurbished options, understanding warranty provisions and support services is paramount in the decision-making process for lab equipment purchases.

How to Evaluate Quality When Buying Used Lab Equipment for Your Research Needs - Evaluating Warranty and Support Options for Used Lab Equipment Purchases

| Equipment Type | Condition | Warranty Period | Support Options | Price Range ($) |

|---|---|---|---|---|

| Incubator | Good | 6 months | Email and phone support | 500 - 700 |

| Microscope | Very Good | 1 year | On-site support and training | 1,200 - 1,800 |

| Centrifuge | Fair | 3 months | Email support only | 300 - 500 |

| Spectrophotometer | Excellent | 2 years | 24/7 support | 1,500 - 2,500 |

| Autoclave | Good | 1 year | Phone support | 1,000 - 1,500 |

Analyzing Manufacturer Reputation and Product Reviews for Quality Assurance

When purchasing used lab equipment, evaluating the manufacturer’s reputation and product reviews is crucial to ensuring you invest in quality. A reputable manufacturer is often a reflection of reliability and performance in their products. Researching the history of the company and its standing within the industry can provide insights into their commitment to quality and customer satisfaction. A manufacturer with a long-standing presence and positive feedback typically indicates a trustworthy source for equipment.

Product reviews offer additional perspectives on the quality of used lab equipment. Engaging with existing users' experiences helps paint a picture of the equipment’s performance over time. Look for reviews that specifically address aspects such as durability, ease of use, and functionality. By focusing on these evaluations, you can make an informed decision that aligns with your research needs, ensuring you select equipment that not only meets your operational requirements but also stands the test of time.

Comparing Cost vs. Benefits: Making Informed Decisions on Used Lab Equipment

When considering the purchase of used lab equipment, it's crucial to strike a balance between cost and benefits. A recent report from Lab Equipment Market Trends indicates that slightly over 50% of researchers opt for used equipment to manage tight budgets, while still adhering to high-quality standards. Understanding the differences between new and used equipment can save significant resources without compromising your research integrity.

**Tip 1:** Always review the equipment’s certification and maintenance records. Equipment should ideally come with a validated history of its use, which not only guarantees reliability but also helps maintain compliance with research standards.

While the upfront costs of used lab equipment may seem lower, it’s essential to consider the long-term benefits it can provide. For instance, according to a study published in the Journal of Lab Science, institutions that invest in quality used equipment report up to 20% savings in overall research budgets, allowing them to reallocate funds towards innovative projects.

**Tip 2:** Factor in the potential cost of repairs when assessing used equipment. A higher initial investment might lead to reduced long-term maintenance costs, ensuring uninterrupted research activities.