Global Demand Meets Quality Assurance in Chinese Smart Manufacturing Lab Products

In the ever-evolving landscape of global manufacturing, the demand for high-quality lab products has surged, particularly in the realm of smart manufacturing. According to a recent report by MarketsandMarkets, the global lab products market is expected to reach approximately $44.7 billion by 2025, driven by advancements in automation and precision technologies. Chinese manufacturers have recognized this trend and are actively enhancing their capabilities in producing sophisticated lab products that meet international quality standards. As industries worldwide increasingly pivot towards innovation and smart solutions, the integration of quality assurance in lab products is paramount. This ensures that the products not only meet regulatory requirements but also enhance efficiency and reliability in laboratory settings. The future of lab products is thus poised for a transformation, where quality assurance and smart manufacturing converge to cater to the escalating global demand.

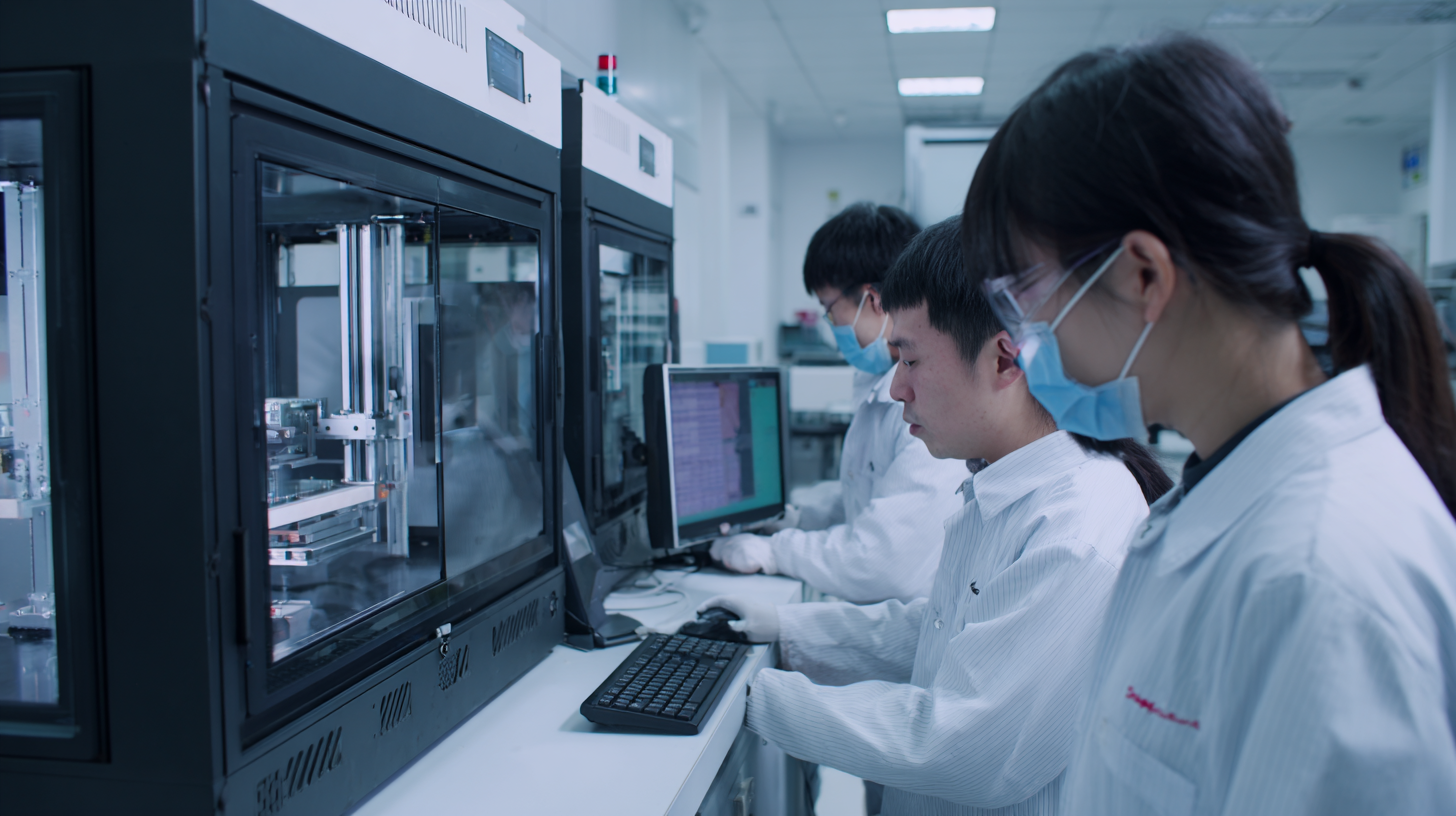

Global Trends in Smart Manufacturing: China's Role and Influence

China has emerged as a pivotal player in the realm of smart manufacturing, significantly influencing global trends through its advanced lab products and technologies. With the rapid evolution of Industry 4.0, Chinese manufacturers are at the forefront of integrating cutting-edge automation, data analytics, and artificial intelligence into their production processes. This shift not only enhances efficiency and precision but also addresses the escalating global demand for quality assurance in manufacturing. The ability to produce high-quality lab equipment that meets international standards positions China as a desirable partner for countries seeking reliable manufacturing solutions.

Moreover, China's strategic investments in research and development further bolster its influence in the smart manufacturing landscape. By fostering innovation and embracing sustainable practices, Chinese manufacturers are setting new benchmarks for quality and performance. The global market is taking note, as industries ranging from electronics to pharmaceuticals increasingly rely on Chinese-made lab products to meet their evolving needs. This intersection of quality assurance and global demand underscores China's critical role in shaping the future of smart manufacturing on a worldwide scale.

Quality Assurance Standards: Key to Global Market Acceptance

In today's global marketplace, the significance of quality assurance standards cannot be overstated, especially within the realm of Chinese smart manufacturing lab products. As competition intensifies, manufacturers are increasingly recognizing that adherence to internationally recognized standards is essential for gaining market acceptance. This trend is further amplified by the demand for sustainable and innovative solutions across various industries. Companies are investing in advanced quality control mechanisms to ensure their products not only meet but exceed these standards.

Recent developments highlight the importance of robust quality assurance processes. For instance, advancements in sustainable building materials demonstrate how quality assurance frameworks are applied to enhance product reliability and performance. Similarly, the introduction of comprehensive quality assurance services in sectors like healthcare underscores the growing need for accountability and trust in product offerings. As firms navigate the complexities of global trade, implementing effective quality assurance measures will play a fundamental role in achieving success and maintaining a competitive edge.

Case Studies: Successful Chinese Smart Manufacturing Lab Products

Smart manufacturing is transforming the global landscape, with China emerging as a leader in producing cutting-edge lab products that meet stringent quality assurance standards. Recent industry reports indicate that the smart manufacturing market in China is projected to grow from $242 billion in 2020 to over $480 billion by 2025, showcasing the rapid advancement and adoption of intelligent technologies. Notable case studies spotlight successful innovations, such as intelligent automated testing systems and advanced robotic arms used for precision manufacturing, demonstrating how Chinese brands are not only meeting but exceeding international quality benchmarks.

To enhance your understanding and engagement with this evolving sector, consider adopting these tips: First, invest in training programs that focus on the latest smart manufacturing technologies, as they are crucial for maintaining competitive advantage. Second, build collaborative partnerships with technology providers to leverage their expertise and integrate state-of-the-art solutions into your operations. Lastly, regularly review quality assurance processes in light of evolving industry standards to ensure compliance and innovation.

With continuous improvements and focus on quality, Chinese smart manufacturing lab products are set to thrive on the global stage, providing critical support for various industries, from automotive to electronics, and paving the way for a smarter future.

Global Demand Meets Quality Assurance in Chinese Smart Manufacturing Lab Products

| Product Category | Application Area | Quality Standard Compliance | Market Demand Level | Customer Satisfaction Rate |

|---|---|---|---|---|

| Automated Lab Equipment | Biotechnology | ISO 9001 | High | 95% |

| Smart Sensors | Pharmaceuticals | CE Marking | Medium | 90% |

| Laboratory Information Management Systems (LIMS) | Clinical Research | FDA Compliance | High | 93% |

| 3D Printing Solutions | Material Science | ISO/ASTM | Growing | 89% |

| AI-Driven Analytics Tools | Environmental Testing | ISO 14001 | High | 92% |

Impact of Technology on Quality Control in Chinese Manufacturing

In recent years, the impact of technology on quality control in Chinese manufacturing has become increasingly significant. As global demand for high-quality products surges, manufacturers are leveraging advanced technologies such as AI, IoT, and big data analytics to enhance their quality assurance processes. These innovations enable real-time monitoring of production lines, allowing for immediate adjustments that can prevent defects and ensure consistency in product quality. Consequently, these technological advancements not only boost operational efficiency but also cultivate greater trust among consumers and businesses alike.

Tip: Implementing a comprehensive quality management system that integrates smart technologies will help businesses stay ahead of the competition. Regular training for staff on new technologies can further ensure that quality standards are met without compromise.

Moreover, automation plays a pivotal role in streamlining quality control processes in Chinese smart manufacturing labs. Automated inspection systems equipped with machine vision can detect minute defects that may go unnoticed by the human eye. This precision minimizes waste and rework, reinforcing a culture of quality within manufacturing environments.

Tip: Regularly updating your quality control protocols to incorporate the latest technological advancements can significantly enhance product reliability and consumer satisfaction. Engaging in industry partnerships can also facilitate knowledge sharing and innovation in quality assurance practices.

Future Outlook: Sustainability and Innovation in Chinese Smart Manufacturing

As the global demand for high-quality manufacturing products continues to surge, Chinese smart manufacturing is emerging as a vital player in the industry. This paradigm shift focuses not only on meeting demand but also on integrating sustainability and innovation into manufacturing processes. Companies in China are increasingly investing in advanced technologies such as AI and IoT to enhance production efficiency while minimizing environmental impact.

To navigate this landscape successfully, consider these tips for embracing sustainability in manufacturing: first, adopt energy-efficient technologies that reduce waste and lower carbon footprints. Next, prioritize sourcing materials from sustainable suppliers to foster a more responsible supply chain. Lastly, engage in continuous innovation by exploring new business models that promote circular economy principles—this can not only boost competitiveness but also meet the growing consumer demand for eco-friendly products.

Innovation will play a crucial role in determining the future of Chinese smart manufacturing. As businesses look to differentiate themselves in a crowded marketplace, embracing cutting-edge solutions, such as automation and advanced data analytics, can lead to smarter processes and superior product offerings. By staying ahead of trends and integrating sustainable practices, manufacturers can ensure long-term success in a rapidly evolving industry.